7: Re-fitting The Flywheel & Final Set-up

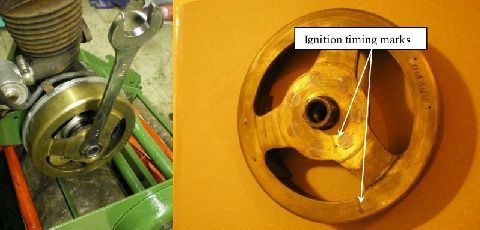

Hold the contact breaker arm open while refitting the flywheel on to its tapered shaft. There are timing marks on the flywheel which should be aligned with the notch on the crankshaft end. This will ensure correct spark timing.

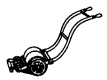

The flywheel nut will need to be tightened sufficiently to prevent any movement on the tapered shaft. If it is slightly loose, the flywheel may slip following a misfire, the timing will be compromised and the engine will run either roughly or not at all. Therefore, tighten the flywheel using the ring spanner and hammer arrangement previous described for removal, but this time for tightening (clockwise).

Finally, re-set the contact breaker points gap.

Check for a spark by unscrewing the spark plug, attaching the H-T lead and resting the threads of the plug against the surface of the cylinder’s cooling fins.