Atco B30 clutch issue

My B30 clutcth is very slow disengaging, to the point where it is a little dangerous.

Such a heavy machine which at speed has a lot of momentum.

At slow speed it disengages quite quickly, but at high speed it takes a couple of seconds before completely disengaging.

It is the newer model with opc bar. On ispection everything seems fine and the cable looks to be correctly set.

It is only at high speed that the delay seems to occur.

Can anyone give me any pointers as to what the issu may be?

Forums

Unfortunately I’ve not got a…

Unfortunately I’ve not got a decent illustration or parts list for the OPC set up, and I’ve not got an OPC machine to refer to , so from memory …….

It’s possible that over the winter the steel plates of the clutch have corroded a bit and are dragging against the Ferrodo friction plates . With the clutch disengaged ( OPC bar released) there should be a bit of “ rattle between the plates.

Probably can do with the clutch taken apart ( engine off) and everything cleaned off to ensure that the pressure plate can move freely and isn’t causing clutch drag when you release the OPC bar. With the OPC bar released there should be just a bit of clearance between the thrust bearings and the pressure plate. With the cover off , apply the drive and watch the interaction between the thrust bearings and the pressure plate. When the bar is released the pressure plate should release the pressure on the clutch plates without delay .

Perhaps someone who is currently working with OPC machines can comment.

The clutch plates all rattle…

The clutch plates all rattle around nice and loose when the clutch is released.

There seems to be something else causing friction between the shaft on the engine side and the shaft on the drive side.

Will need to come apart to investigate fully I feel.

Within the clutch housing, does the one shaft perhaps fit inside the other one, I'm not sure.

But something there is dragging.

Well, there will be a spigot…

Well, there will be a spigot bearing ( possibly a bush ) supporting the end of the output shaft on the engine crank shaft, and if that’s binding a bit, there’s the issue.

Hopefully some one can post the appropriate “exploded” illustrated parts diagram, all mine are pre OPC.

Thanks wristpin. TBH I don't…

Thanks wristpin.

TBH I don't think the opc is even relevant to my problem.

If anyone has any details/drawings on how the shafts mate up within the clutch housing area, it would probably help.

Anyway, looks like I need to move the engine away.

4 bolts out and then just jiggle it to the side a bit I presume?

Yes, thinking about it , you…

Yes, thinking about it , you are correct. The OPC is really just a reversal of the original release / engagement system. Getting the engine out of the way is the way to go. Just need enough room to place it securely without upsetting the throttle cable and any electrical connections. May be a good idea to take A few phone or camera images as you go. Meanwhile I’ll try and find some reasonably up to date illustrations.

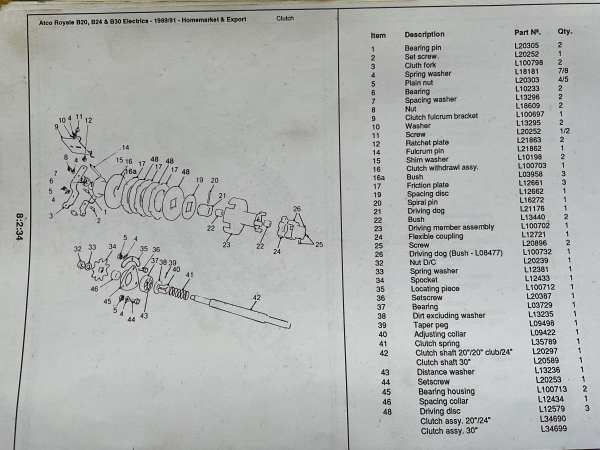

Hope that this may help. The…

Hope that this may help. The engine end of the shaft 42 is supported in the bushes 22 in the clutch basket 23 which they call the driving member assembly . Your issue could be that those bushes are binding on the shaft and transmitting some drive even when the clutch plates are not engaged.

So, on clutch disassembly, 2…

So, on clutch disassembly, 2 of the friction plates basically broke up into 2 or 3 pieces each.

Not sure it this was the cause of the mower struggling to disengage, but they certainly need replacing now.

£30 each though, wow, has anyone got a source for a pattern equivilant?

Well that’s definitely the…

Well that’s definitely the reason for it not disengaging - bits of broken plate occupying space that should be clear. No telling why they broke . Was it ok at the end of last season? Possibly sticking to the steels over winter or dare I say it, operator brutality 🤭 . Not aware of any pattern equivalent but may be worth an eBay of FB search. When I was in the trade we sold very few of those plates considering that we looked after many 20, 24 and 30” HD Atcos that all used the same plates from before 1960 !

Ok, so it looks like someone…

Ok, so it looks like someone is selling some pattern replacements on ebay at 15 ea, feedback looks good.

Think, I'll probably just replace all three, while I'm at it.

I have no clue as to why or when they broke.

The clutch was never particulary good, so may have been like it when I got the mower some 12months ago now.

So the friction plates don't tend to break under normal use?

The clutch plates appear to…

The clutch plates appear to be all in good shape.

With the clutch released there is approx 4mm of clearance in total and all plates are free to move.

Under higher revs there seems to be too much inertia and the shaft from the engine seems to carry on turning the drive mechanism.

Reving high with the clutch disengaged the mower will actually tend creep forward unless you hold on to it.