1921 Atco Standard - engine help requested

Hello

This is my first post on this excellent forum. I made use of the content when I restored a Ransomes mower previously. I've now inherited two Atco Standard 22" mowers and thought it was high time I joined. I'm now very glad I did as I've started tackling the first of them and I'm hoping to get some help from members here.

One of the mowers belonged to my wife's grandfather and the other to her great uncle. Based on the information about these mowers on this forum, I've dated one of them as the 1921 model on account of its oval cross-sectioned frame. The other is younger but in worse condition. I've decided to see if I can get the 1921 mower working first.

The mower is really not in bad condition for its age. The engine turns over nicely on the starting handle and there seems to be compression. I'm told by my wife's uncle that it started last time he tried it, but I've worked out that was around 40 years ago...

My first test was to see if there is a spark. There is not, and that's what I've been investigating. (I'll look at the fuel system once I've got a spark.)

Trying to investigate things in order of ease and cost (cheapest first!), I have:

1. Bought a new spark plug. Still no spark.

2. Tested the HT lead for continuity. There was none so I've made up a new lead. Still nothing.

3. Removed the flywheel and the coil (the flywheel was really tight! I've attached a photo of my method for holding it which seemed to work well). It seems to me that there is no continuity in the coil (although I want to check I'm testing properly) which I understand is bad. I think I'm right in saying that having continuity doesn't guarantee the coil is good, but no continuity is a problem?

My questions for anyone who is able to help are:

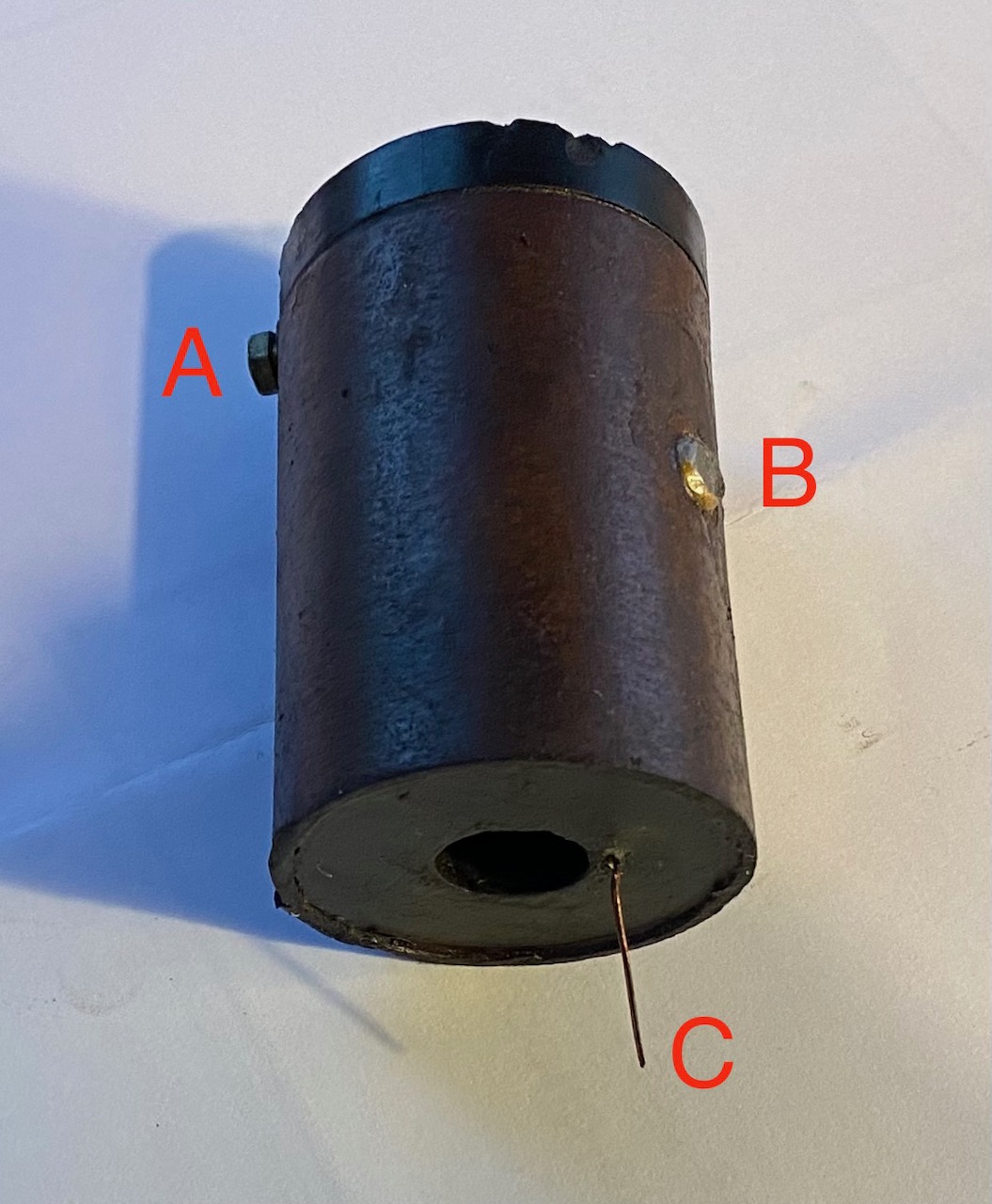

A. How should I be testing the coil? Is it point A to C, A to B or B to C? I have continuity between A and C, but not A/B or B/C.

B. If the consensus is that coil is dead, is there any advice on how to go about replacing it - i.e. where to buy from and how to choose the right one?

C. If I replace the coil, should I also replace the condenser while I'm at it?

D. Are there any other steps I've missed/should be thinking about?

Thanks in advance for any help you can give me.

Nick

Forums

Thanks Adrian That's helpful…

Thanks Adrian

That's helpful. I'll have a look at the link.

If it's the original coil, it wouldn't be surprising if it's dead after 100+ years!

Unfortunately they're a bit speedy, but I can live with spending a bit on such a venerable old machine.

I'll also have a look at the coil in the other mower although I have even less hope for that one!

thanks

Nick

George at Villiers Parts is…

George at Villiers Parts is your man for a decent coil and a condenser . The chances are that the windings of your coil will be full of green corrosion, and are not fit for further use. When assessing coil condition, it is the resistance of the primary and secondary windings within the coil that ate the deciding factors. B to C secondary and A to C primary.

I like your flywheel clamping device - very similar to my one for dealing with seized Ransomes Marquis rear rollers.

Thanks Wristpin I'm getting…

Thanks Wristpin

I'm getting nothing on the secondary (i.e. open circuit).

I'll be giving George a call to discuss what I need.

I saw your roller clamping arrangement when I restored my Ransomes. The roller was seized but I ended up taking one from another mower that I bought on eBay. I've still got the original one to tackle at some point.

Thanks again

Nick

Nice to find another of…

Nice to find another of these "Oval Frame" Standards in preservation.

The coil on the Villiers Mk V 269cc engine used in the original 22in Atco Motor Mower (ie the Oval Frame Standard) is larger than those on the MkVI-C 247cc engines generally used on the the later 22in models, which are much more common. The units are not readily interchangeable because of the size but it's not impossible to fit the smaller coil into the 269cc engine using suitable sleeves and shims etc (I think we had an article in a very early Grassbox about this or perhaps a web page).

However, if you are planning on running the mower regularly (and why not, many of us do) then it's well worth getting a replacement of the right size or asking for the current unit to be rewound. As wristpin has suggested, Villiers Parts can probably help but there are other sources. While you're at it, replacing the condenser is a good idea too as both are essential for the best possible spark. Something you didn't mention, but presumably you have done, is to make sure the points are clean and opening and closing properly.

Incidentally, there is a special section on our website about the rebuild of a similar magneto (Villiers used the same system from just after WW1 well into the 1950s) where you'll find lots of useful advice and pointers:

https://oldlawnmowerclub.co.uk/general-technical-help/villiers-magneto-…

Finally, the site has a huge amount of information about the Atco Standard in its various forms, including the original 22in model, such as copies of the orginal hand book, parts list, and so on:

https://oldlawnmowerclub.co.uk/technical/mowers/atco-oval-frame-motor-m…

Thanks, that's very helpful…

Thanks, that's very helpful.

Taking measurements off my coil, I was coming to the same conclusion about the coil being larger on these earlier engines. I'm in touch with George now and discussing what I need.

Mechanically the points are working well, but I do intend to give them a really good clean.

The information on the site is incredibly helpful. I've already been able to tell my wife's uncle that one of the mowers is older than the 1927 date he had in mind.

Thanks again

Nick

Looks as though you are well…

Looks as though you are well equipped for the job in hand and may be a bit more! That Myford may be needed to to make extensions for the core of a smaller coil to fit between the larger pole pieces of your magneto. Depends on what George suggests. Keith mentions the points. Definitely worth changing and small beer compared with the coil and condenser. Certainly the heel of yours looks a bit worn.

Jumping ahead to the reassembly of the mag and refitting the flywheel , you may see reference to using the Atco special tool, the Hammertight or flogging spanner for tightening that nut that gave you grief on dismantling - no torque figures given in those days. I’ve collected a couple of different sizes and patterns over the years , and they still crop up on auction sites.

Thanks Wristpin

Thanks Wristpin

On the subject of age, the…

On the subject of age, the oval frame is easy to date. The other is going to be guesswork as the only date is given by the prefix to the number on the flywheel. It's been discussed here a few times that if machines went back to Atco for fettling there was no guarantee that the same bits would come back. When I found my Standard it had three diferent Atco badges on the tank from, presumably, 3 repaints - I've a 1960s brochure in a heap somewhere with a pic in it of a Standard being refurbished at the factory. My machine is an 18", launched in 1926, but the engine has a 1923 prefix - so you pays yer money and you takes yer choice datewise.

When I collected them from…

When I collected them from my wife's uncle, I was told one of the was 1927 and the other 1928. However, one of those dates is definitely wrong given the oval frame! It would be nice to know when the younger one has its 100th birthday. I'm expecting a card from the King!

Sorry, it has been a while…

Sorry, it has been a while since I posted about this, but I can now give an update.

I bought a coil from George Shead. I was slightly annoyed it wasn't a direct replacement because I'd been clear about what I needed and was told one could be supplied, but I understand things aren't straightforward when dealing with 100+ years old machines!

Rather than get the existing coil rewound, I decided to adapt the replacement. I can always go for a rewind if I decide I want to keep everything as original as possible. Adapting the replacement also gave me an opportunity to use my (relatively newly acquired) lathe!

Stupidly I didn't take any photos before I reassembled everything, but essentially I had to make two "top hat" adapters for the core ends of the new coil. These had flats filed onto them so that they fitted into the rectangular slots on the "cheeks". They were also drilled to accept the screw that holds the whole assembly onto the back plate.

While I had the magneto assembly in pieces, I also took the opportunity to replace the condenser, clean the points, and generally give it all a clean up.

Because the replacement coil is a smaller diameter than the original, I wondered if the spring loaded plunger on the HT lead would reach, or if I would need to make a longer one. It was hard to see, but I did have continuity between the coil and the spark plug so it seemed OK.

I installed the reassembled magneto on the mower and set the points and timing. I was very pleased (and frankly amazed) to see a healthy spark!

Having sorted the electrical…

Having sorted the electrical side of things, I then had a look at the fuel system.

I gave the carb a bit of a strip down and clean up and also flushed out the fuel line. I actually expected the the full line (which has a braided metal outer and, I assume, rubber inside) would have perished, but as far as I can tell, it doesn't seem to leak which is miraculous.

Nothing else for it then to mix up some petrol/oil and give it a try.

It started! It took a few goes, but it is actually quite easy to start using the decompression lever,

It seems to run reasonably well. There is a bit of a bang in the firing sequence. I don't know if that's normal or if it's backfiring. If the latter, query if that's because the timing is a bit out or the air lever on the carb isn't set right (the manual mentions something about that).

The clutch and drive mechanisms seem to work as they should, but I need to get it onto the lawn to test it properly.

One question: is a generic modern two-stroke engine oil suitable for an engine of this age or is there something specific I should be using?

“Old oil for old engines.” …

“Old oil for old engines.” I believe that Villiers would have recommended a 16:1 mix using a straight SAE 30 non detergent motor oil, such as Castrol XL. An oil with a bit of body helps with sealing worn crankshaft main bearings which are plain bushes without conventional seals. Millers Oils do both a 30 and 40 oil blended for two stroke vintage and veteran motorcycles .

Thanks Wristpin

Thanks Wristpin

Welcome on board, Nick! May…

Welcome on board, Nick! May I say "Nice pair of Standards!".

It might be safer to assume that your coil is kaput anyway - I bought one for my (later) Standard from George Shead here: http://www.villiersparts.co.uk/contact.html, though I don't know if your engine shares a coil with the MkVI-C on my Standard, it looks bigger diameter.

Somewhere on here there is my 2020 "Spring holiday" thread with lots of pics of changing the coil on a MkVI-C engine, which will probably help you, though it looks as though you know more than I do about workshops already, I did mine on what passed for a patio!